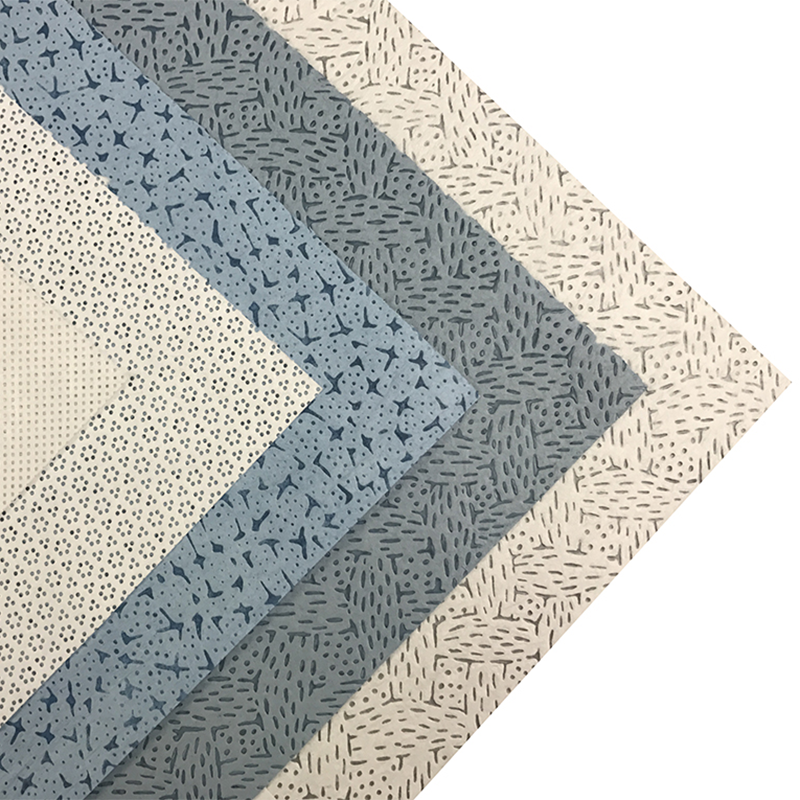

I. Material Electio et Processus: ESD Wiper Usus compositum polyester aut microfiber et summus perficientur permanens PROMPTIVUS fibra. Per specialem knitting et texit processibus, fibris sunt magis arcte tenetur et possibilitate fibra effusione reducitur. Ordinatio et densitate fibris sunt pressius imperium ad augendae structural stabilitatem fabricae.

II. Superficiem Design: Quod gere, repugnans superficiem consilio ESD Wiper amplio in diuturnitatem ex uber, reducit frictionem et gerunt quod potest fieri per deleretur, et vitat effusione fibris et obstantia. Hoc consilio ensures quod productum potest ponere integritas et Purgato effectus post iterari usum et Purgato.

3. Clean room packaging: ESD Wiper uses clean room packaging technology in the production process to ensure that the product is in an environment with low particles, low ions and low non-volatile residues before leaving the factory, reducing the possible sources of pollution during use and improving the cleanliness and user experience of the product.

IV. Chemical inertness: De materia ESD Wiper habet bonum eget compatibility. When it comes into contact with various chemicals and cleaning agents, it will not undergo chemical reactions or material degradation, thus avoiding fiber shedding and debris falling due to chemical reactions, ensuring its stability and reliability in various complex and harsh use environments.

Український

Український